| 1. |

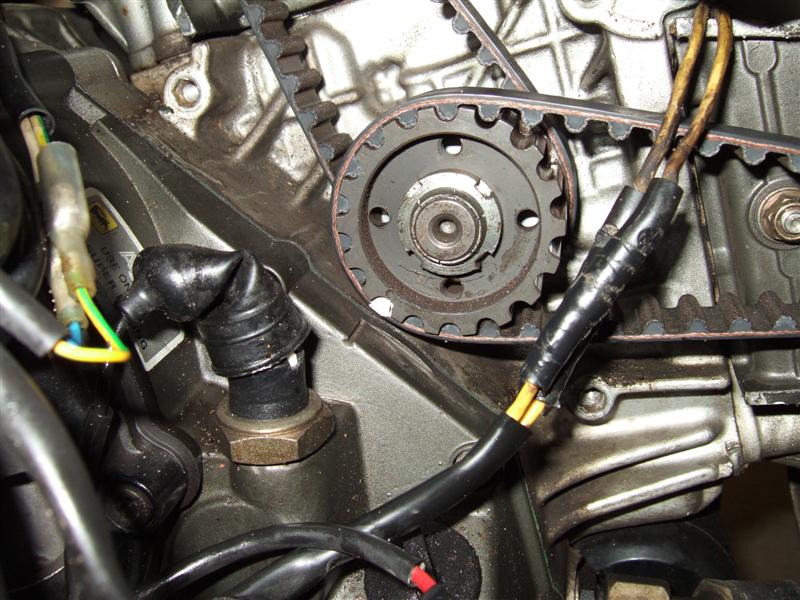

| Where are the belts?, behind all that stuff

!! |

|

|

| 2. |

| Remove the battery, the battery tray and

pull the wires out of the way.. |

|

|

| 3. |

| Remove the fuel tank, the quick detach

couplings help. |

|

|

| 4. |

| Remove the 2 induction trumpets, 1/4 turn

frees them off. |

|

|

| 5. |

| Remove the air box |

|

|

| 6. |

| Remove the black crank case breather to give

more room behind the head, plus take out the spark plugs. |

|

|

| 7. |

| Better view now ( crank case breather not

yet removed ! ) |

|

|

| 8. |

| Having removed the spark plugs you can now

put the bike in top gear and then turn over the engine by turning the back

wheel. Note, always turn the engine the correct way, never backwards.

Next line up the timing mark on the end of the crankshaft.

p.s. Those yellow charging wires may need replacing :-( |

|

|

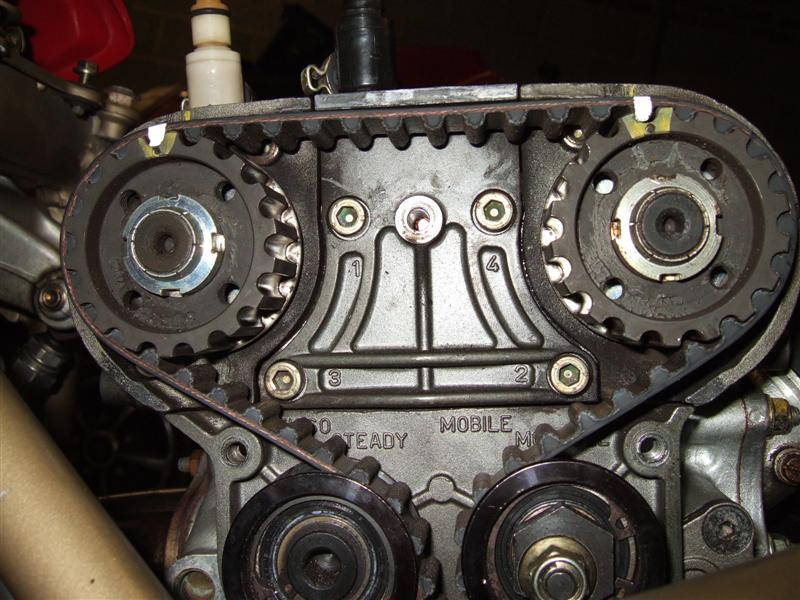

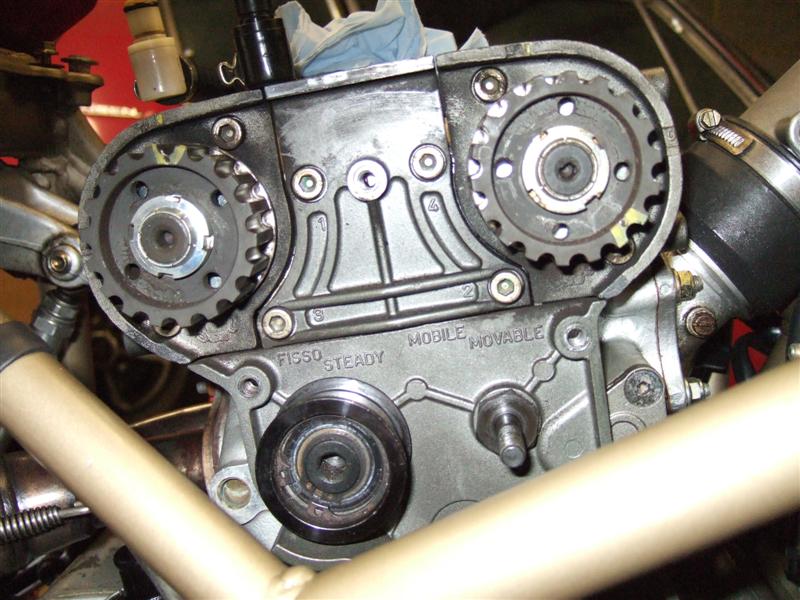

| 9. |

| When you are at the correct timing mark, TDC

on the firing stroke of the horizontal cylinder, all the marks will line

up.

Horizontal head. "o" timing mark on the head. |

|

|

|

| 10. |

| Vertical head. "v" timing mark on

the head. |

|

|

|

| 11. |

| Next you have to go around to the window on

the left hand side of the engine to fine tune the alignment. You can

remove this other cover to turn the engine over with a special tool, or a

long bolt and lock nuts, but I found the back wheel just as good. |

|

|

| 12. |

| The timing mark |

|

|

| 13. |

| Next take off the tensioning pulley from

each cylinder and remove both belts. |

|

|

| 14. |

| Note how the right hand intake sprocket has

spun around on the vertical head when the belt is removed. |

|

|

| 15. |

| This is the belt for the early 916 &

748. Make sure yours has the RED writing. |

|

|

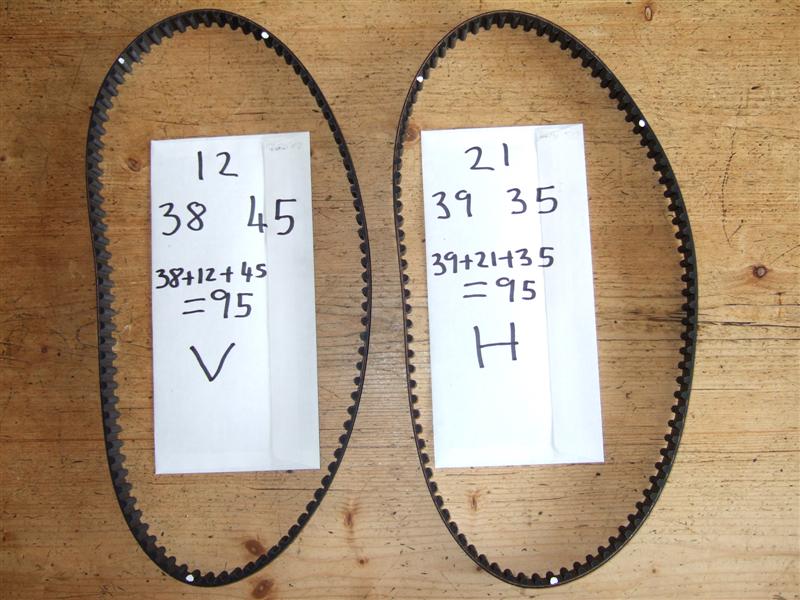

| 16. |

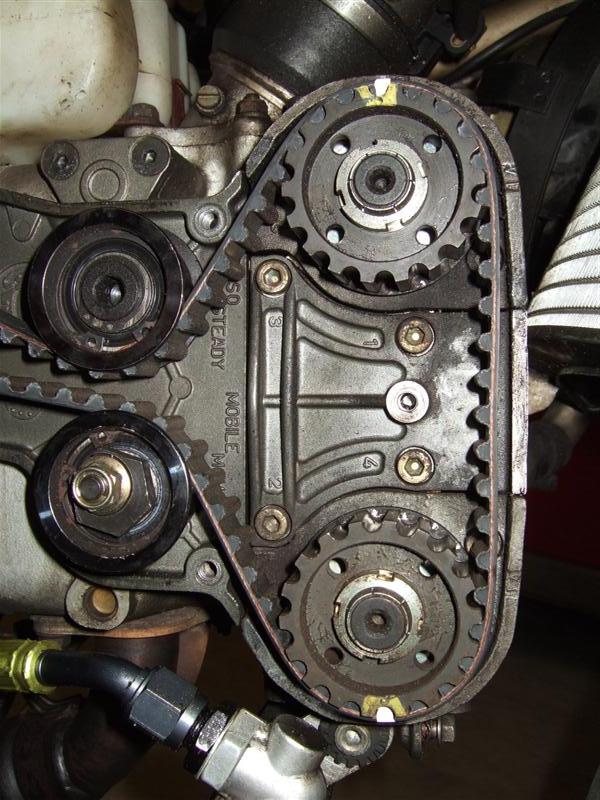

| Next comes the clever bit. Mark up your

belts using Tip-Ex. This makes checking the alignment very easy. On the

vertical belt put the bottom mark on the back of the belt as well,

otherwise you can not re check the mark when the other belt is in place.

Hint, go back to No.10 above and count the 12 teeth (it's 13 if you count

both marks but then the maths below totalling 95 will not work)

For more details check out the Ducatitech website http://www.ducatitech.com/4v/maint/belts/index.html |

|

|

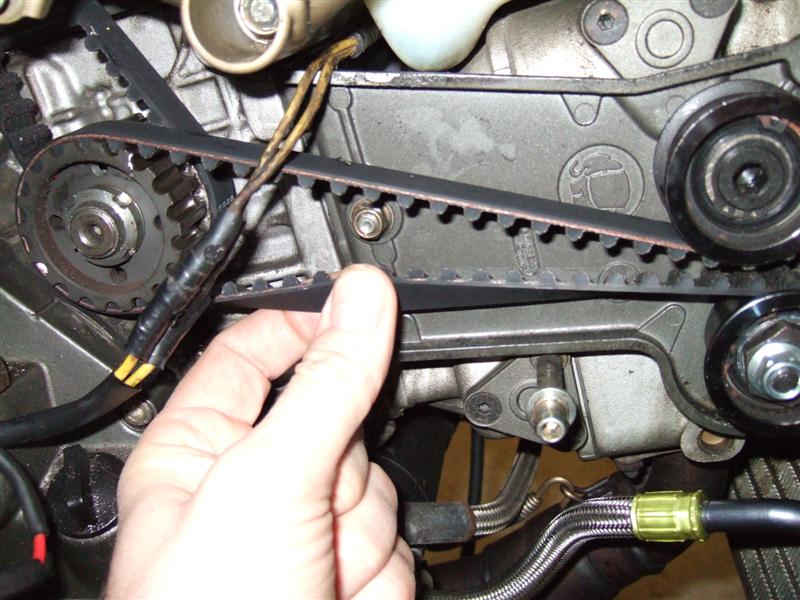

| 17. |

| Belts back on.

The tricky vertical RH sprocket is not a big problem, as the white

marks make sure all the timing marks are right.

Once the belts are on you then put the tensioning pulleys back on and

take up the slack. |

|

|

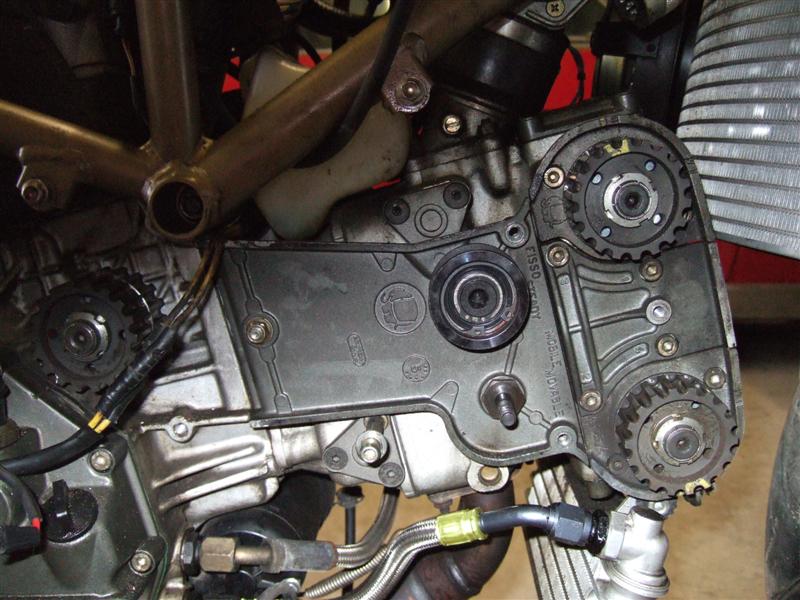

| 18. |

| Turn the engine over a couple of times to

take out any slack, then re-align the timing marks. This time the

white marks on the belts may be in the wrong places. This does not matter

as all we want is TDC on the firing stroke of the horizontal cylinder.

Next you need to set the tension of the belts, turn the tensioning

pulley anti clockwise to make the belts tighter.

Replace the wavy washer and locking nut on the tensioning pulleys with

new ones. |

|

|

| 19. |

| There are lots of different methods of

checking the tension. Try them all to double check your tension.

45 degrees of twist on the longest run of belt. Note this is a 1/4 turn

NOT a 1/2 turn or 90 degrees !! |

|

|

| 20. |

| The Facom tool is about 1/4 price of the

Ducati tool. I had mine checked first against a Ducati one. Ducati John (John

Cellier) http://www.ducati-john.co.uk/

did it for me. You need to use the No.4 spacer, not the No.5 that the

Facom guide suggests. Plus you go for the bottom of the top grove. |

|

|

| 21. |

| Finally I used the 5mm slack method. I used

the push up method, as suggested by Ducati John and some other websites.

In the picture below you will see that a 5mm Allen key just fits

between the top of the belt and the bottom lip of the head casing.

All you need to do is push up, taking up the slack in the belt, and see

how far you go.

You may wonder how hard to push. I found the best method

is to push up and down multiple times (rocking). You then start to get an

average distance, which takes out all the over and under pushing, if you

understand me :-) |

|

|

|

| 22. |

| Don't forget you check the horizontal cylinder

first, while all the timing marks are lined up. You then have to turn the

engine over 270 degrees, to the other timing mark in the window on the LH side of the engine, before you can check the vertical cylinder. At

this engine mark it may be that none of the timing marks on the pulleys will be correct.

The reason you have to turn the engine over is that it then places the

vertical cylinder at TDC on the firing stroke, which takes the turning

force off the RH side inlet sprocket, which would otherwise place extra tension on

the belt. Remember how the sprocket spun around in the picture at No.14

above? |

|

| All done.

Make sure you turn over the engine a few more times using the back

wheel. This is to double check that the timing is right and nothing is

hitting. It does not harm to double check the tension after a few more

turns, just to make sure all is OK. |

|

|